China ingot casting machine manufacturers

China melting furnace suppliers

Ingot casting machine manufacturers

melting furnace suppliers

Lufeng company is a scientific and technological enterprise integrating R & D, production and sales, specializing in scientific research and development, metallurgical equipment, environmental protection equipment and non-ferrous metal purification. It is a national certified high-tech enterprise. It has supporting facilities for various large-scale metallurgical processing equipment and systems, and has passed ISO9001 certification. It can engage in R & D, design, production, installation, commissioning and other related businesses of metallurgy, environmental protection, energy-saving projects and equipment.

News

-

2026-01-12

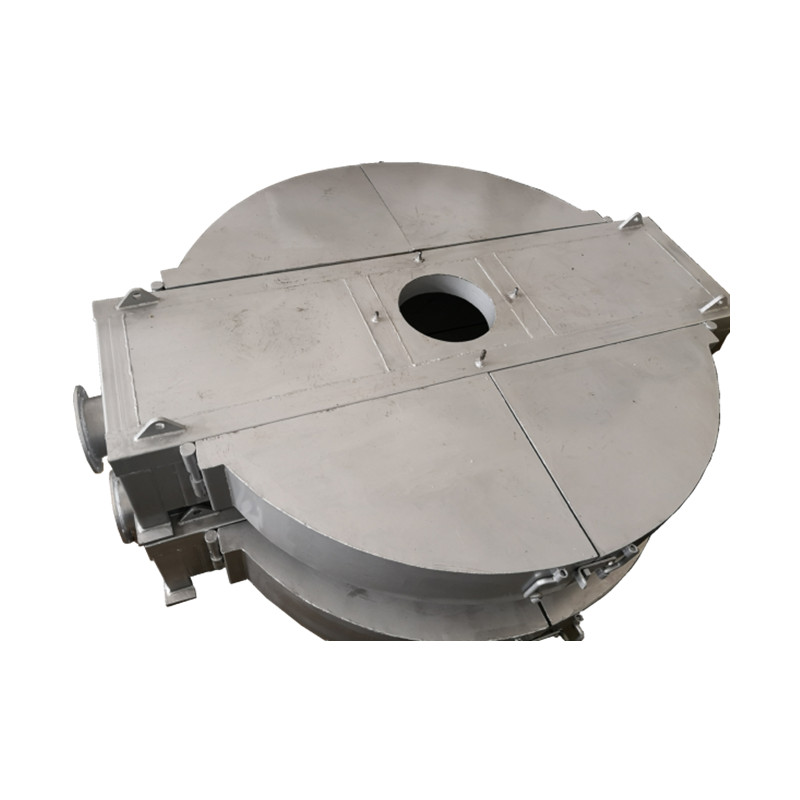

copper slag ingot casting machine is shipping for clients

Read Morecopper slag ingot casting machine is shipping for clients

-

2025-12-26

copper slag ingot casting machine is making for clients

Read Morecopper slag ingot casting machine is making for clients

-

2025-12-11

lead smelt pot is ready for shipping to clients

Read Morelead smelt pot is ready for shipping to clients