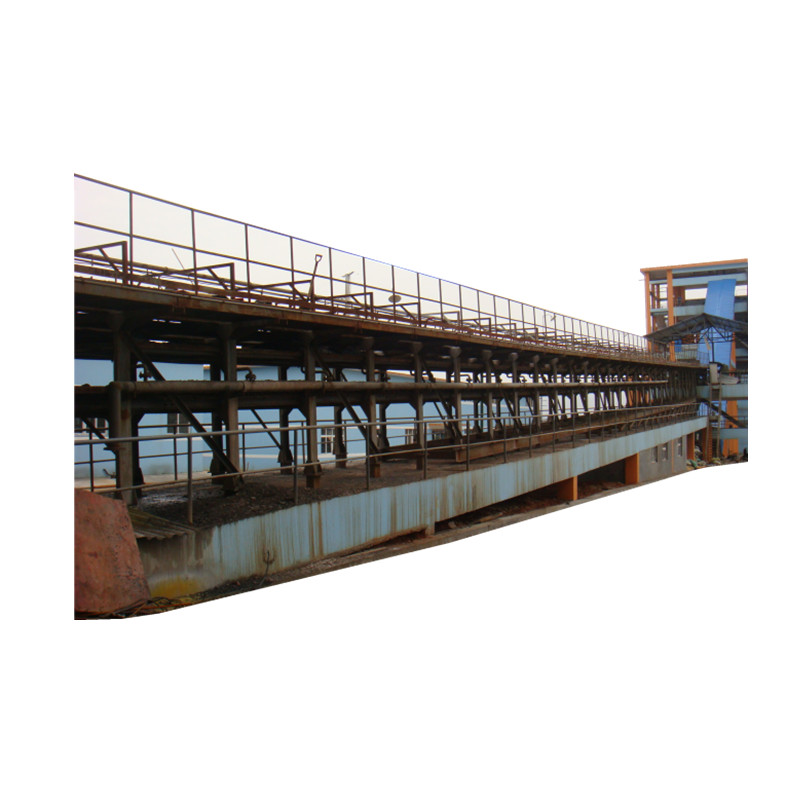

Lufeng is the design and equipment supplier of complete smelting system. It has provided design and related equipment, maintenance, installation, etc. for many copper smelters at home and abroad. The pyrometallurgical workshop should have anode plate disc casting machine, initial pole piece machine, cathode strip machine, residual pole washing machine, etc. The main accessories are mold, sprocket, chain, non-standard heavy bearing seat, shaft, etc

Lufeng has a number of excellent technicians and technicians. There are several supporting equipment for turning, milling, boring, drilling, welding, etc.

The company is mainly engaged in the development, manufacture, installation and commissioning of mining, smelting and engineering machinery. At present, it mainly produces smelting supporting and complete sets of equipment, such as the design and manufacture of automatic production line of lead (zinc / copper / aluminum) ingot casting machine, anode plate casting machine, cathode film making machine, crusher, slag casting machine, mixer, molten metal pump, lead pot and other equipment, as well as the upgrading and transformation of old equipment; Design and production of non-standard equipment.

Lufeng has a mature design team, which can design and manufacture accessories matching customers' equipment according to customers' specific project requirements to meet the interchangeability of products.

English

English  Español

Español  Português

Português  русский

русский  français

français  日本語

日本語  Deutsch

Deutsch  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ไทย

ไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  Malay

Malay  বাংলা

বাংলা  हिन्दी

हिन्दी  Pilipino

Pilipino  Türk

Türk  عربى

عربى  Indonesia

Indonesia  norsk

norsk  čeština

čeština  Українська

Українська  Javanese

Javanese  فارسی

فارسی  తెలుగు

తెలుగు  Burmese

Burmese  български

български  Latine

Latine  Azərbaycan

Azərbaycan  Српски

Српски  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  Cymraeg

Cymraeg  Беларус

Беларус  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Bosanski

Bosanski  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  IsiXhosa

IsiXhosa  Chichewa

Chichewa  Somali

Somali  O'zbek

O'zbek  հայերեն

հայերեն  Sundanese

Sundanese  Malagasy

Malagasy