Lufeng is a Professional metallurgical ingot casting machine design, manufacturing and sales manufacturers in China. We have specialized in ingot casting machine for 12 years and exported our products to more than 15 countries with strong technical support, good quality and services. And Lufeng has added value to Clients by successfully developing complex and innovative projects throughout the world.

Ingot casting machine is a device to receive the refined Molten metal alloy from furnace through fire-refining. the machine is mainly used to cast metal liquid into mould, cool it for condensation of standard ingots, and stack the ingots one layer by one layer automatically. It can achieve full automatic control of the whole production process, so as to improve the production efficiency and save the labour cost, meanwhile the ingot quality is comparatively better.

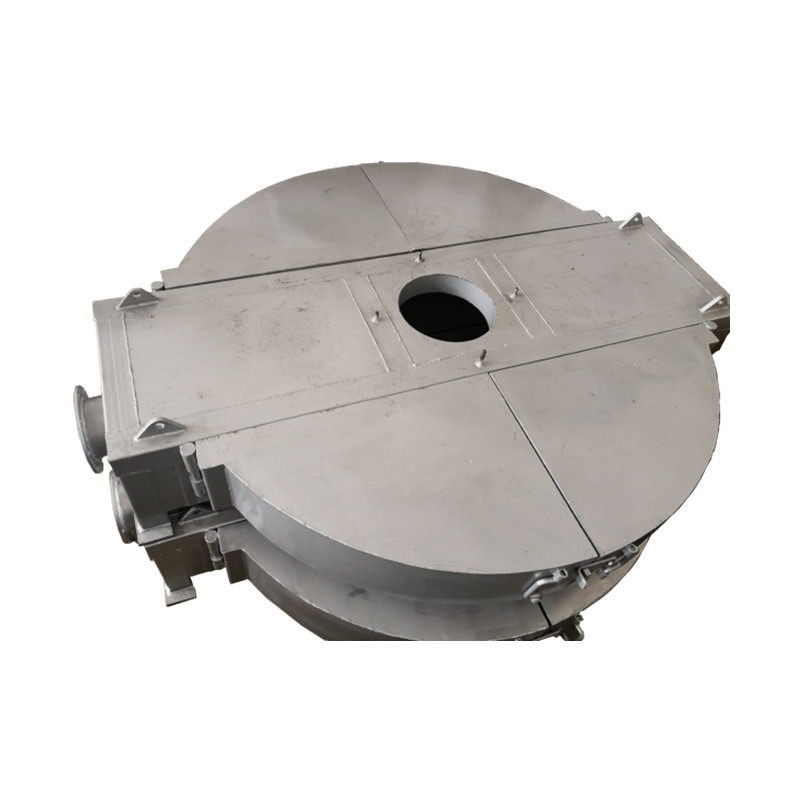

The ingot casting machine integrates function of casting, automatic stacking and packing, etc. the casting system consists of quantitative pouring unit, chain conveyor, slagging-off, bottom water cooling, ingot turnover and packing parts.

Casting module of different size are offered for different ingot specification. the casting precision is less than 5%. the ingot is conveyed by chain for continuous and stable movement. the system works very stable without shaking and thus avoid ripple on the ingot surface.

What are the advantages of ingot casting machine: Automatic ingot pouring and drossing; Consistent size, low dross ingots; Automatic stack weighing, label printing and application; Remote production data reporting and recording; Smooth running casting conveyor with controlled solidification;Cavity and crack free ingots; Superior quality ingot top surface; Stack settling press and floating strapping head Uniform precise stack shape and high visual appeal; Improved operator health and safety.To choose us is to choose health, safety and quality.

English

English  Español

Español  Português

Português  русский

русский  français

français  日本語

日本語  Deutsch

Deutsch  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ไทย

ไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  Malay

Malay  বাংলা

বাংলা  हिन्दी

हिन्दी  Pilipino

Pilipino  Türk

Türk  عربى

عربى  Indonesia

Indonesia  norsk

norsk  čeština

čeština  Українська

Українська  Javanese

Javanese  فارسی

فارسی  తెలుగు

తెలుగు  Burmese

Burmese  български

български  Latine

Latine  Azərbaycan

Azərbaycan  Српски

Српски  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  Cymraeg

Cymraeg  Беларус

Беларус  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Bosanski

Bosanski  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  IsiXhosa

IsiXhosa  Chichewa

Chichewa  Somali

Somali  O'zbek

O'zbek  հայերեն

հայերեն  Sundanese

Sundanese  Malagasy

Malagasy