PRODUCT NAME:

scrap copper recycling machine wheel anode plate disc round casting copper recycle device

The pyrometallurgical process mainly includes four main steps: matte smelting, copper matte (matte) blowing, crude copper pyrometallurgical refining, and anode copper electrolytic refining.

Sulfur smelting (copper concentrate ice copper): mainly using copper concentrate to make ice copper for smelting, with the aim of partially oxidizing iron in the copper concentrate, removing slag, and producing ice copper with higher copper content.

Ice copper smelting (ice copper crude copper): Further oxidation and slagging of ice copper to remove iron and sulfur from it, producing crude copper.

Fire refining (crude copper anode copper): The crude copper is further removed from impurities by oxidation and slagging to produce anode copper.

Electrolytic refining (anode copper cathode copper): By introducing direct current, the anode copper dissolves and pure copper precipitates at the cathode. Impurities enter the anode mud or electrolyte, thereby achieving the separation of copper and impurities and producing cathode copper.

PRODUCT PICTURES:

scrap copper recycling machine wheel anode plate disc round casting copper recycle device

scrap copper recycling machine wheel anode plate disc round casting copper recycle device

scrap copper recycling machine wheel anode plate disc round casting copper recycle device

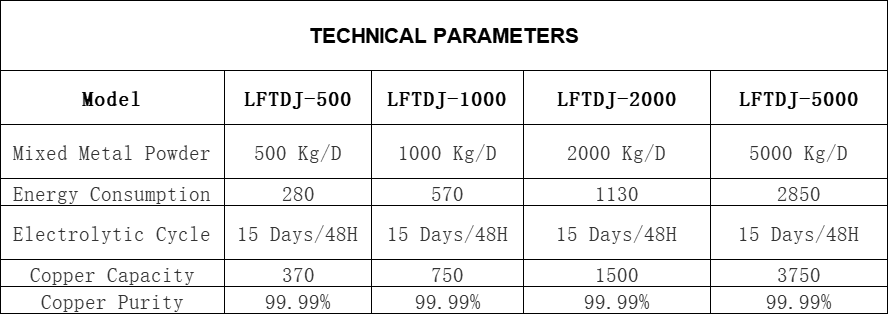

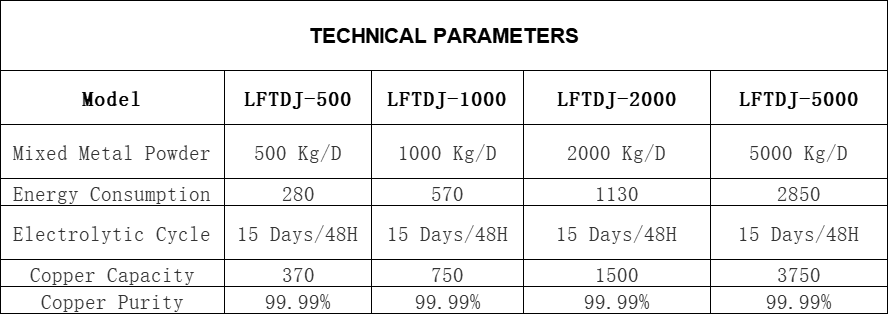

SPECIFICATIONS:

scrap copper recycling machine wheel anode plate disc round casting copper recycle device

English

English  Español

Español  Português

Português  русский

русский  français

français  日本語

日本語  Deutsch

Deutsch  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ไทย

ไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  Malay

Malay  বাংলা

বাংলা  हिन्दी

हिन्दी  Pilipino

Pilipino  Türk

Türk  عربى

عربى  Indonesia

Indonesia  norsk

norsk  čeština

čeština  Українська

Українська  Javanese

Javanese  فارسی

فارسی  తెలుగు

తెలుగు  Burmese

Burmese  български

български  Latine

Latine  Azərbaycan

Azərbaycan  Српски

Српски  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  Cymraeg

Cymraeg  Беларус

Беларус  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Bosanski

Bosanski  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  IsiXhosa

IsiXhosa  Chichewa

Chichewa  Somali

Somali  O'zbek

O'zbek  հայերեն

հայերեն  Sundanese

Sundanese  Malagasy

Malagasy