washing machine

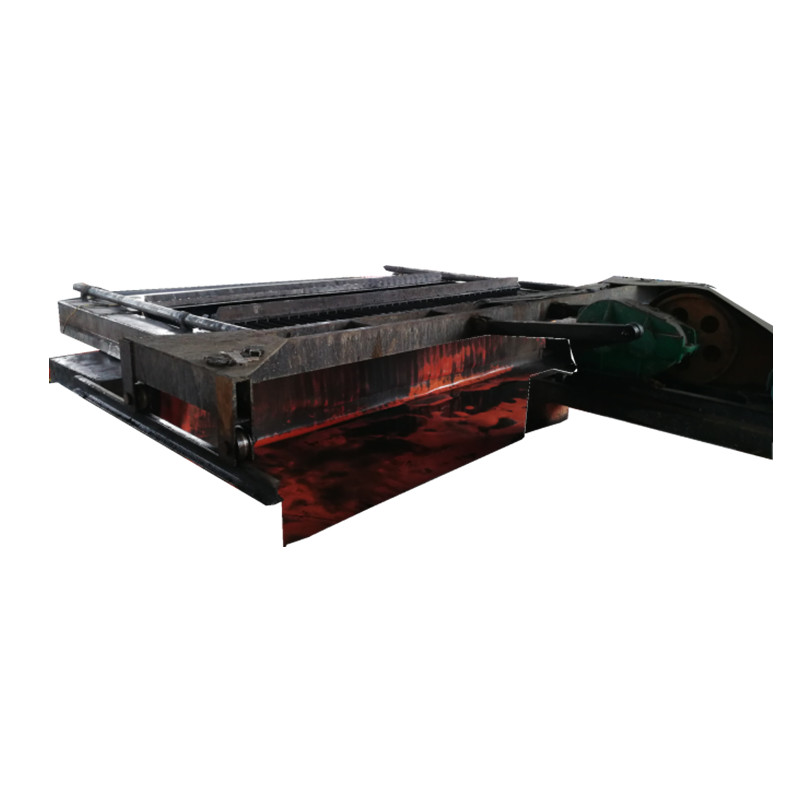

PRODUCT NAME: Lead anode scrap washing machine

In the process of lead electrolytic refining, metal lead loses electrons at the anode and becomes lead ions that enter the electrolyte. Lead ions precipitate after receiving electrons at the cathode. Except for a small portion of impurities in the anode that dissolve with lead into the electrolyte, the vast majority of them are insoluble and adhere to the surface of the anode to form anode mud. The anode mud contains a large amount of lead, antimony, bismuth, and precious metals such as gold and silver. Therefore, it is necessary to clean the attached anode mud and residual acid for recycling to reduce repeated smelting. At present, there are three main types of washing equipment for lead electrolysis anode mud in China: horizontal residual electrode washing machine, vertical residual electrode washing machine, and rotary residual electrode washing machine.

PRODUCT PICTURES:

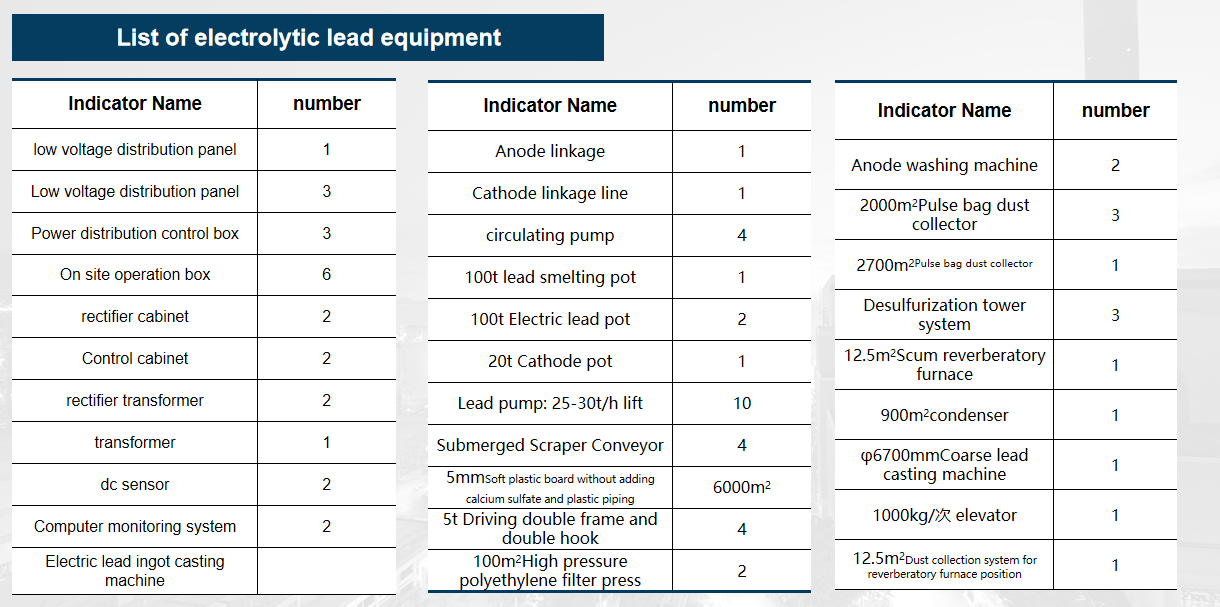

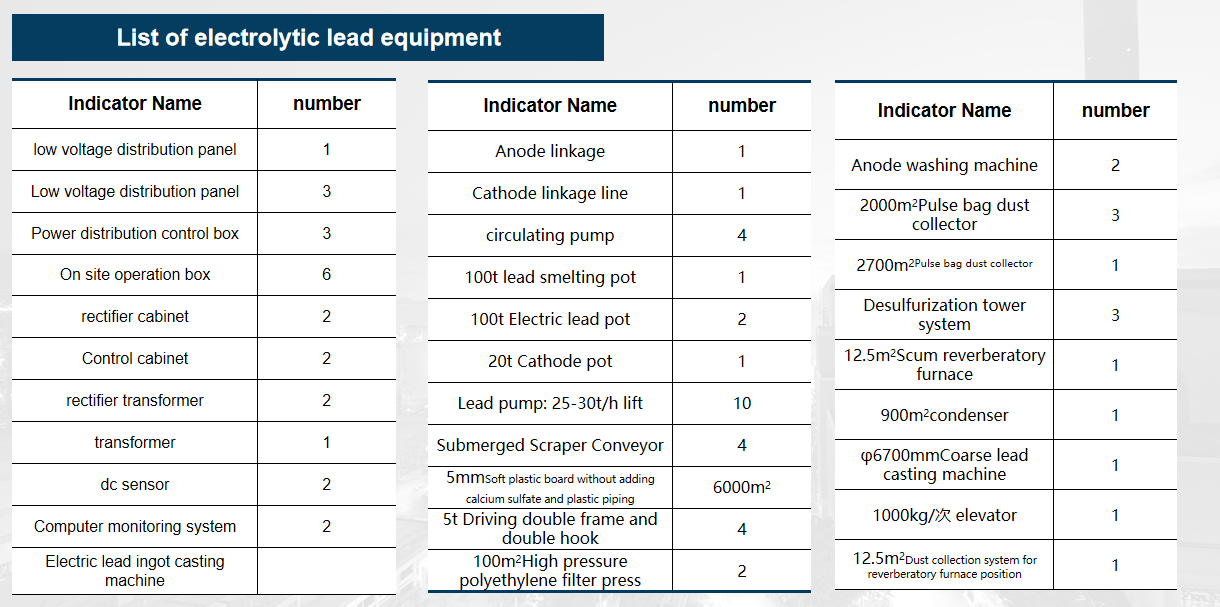

SPECIFICATIONS AND PROCESS:

English

English  Español

Español  Português

Português  русский

русский  français

français  日本語

日本語  Deutsch

Deutsch  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ไทย

ไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  Malay

Malay  বাংলা

বাংলা  हिन्दी

हिन्दी  Pilipino

Pilipino  Türk

Türk  عربى

عربى  Indonesia

Indonesia  norsk

norsk  čeština

čeština  Українська

Українська  Javanese

Javanese  فارسی

فارسی  తెలుగు

తెలుగు  Burmese

Burmese  български

български  Latine

Latine  Azərbaycan

Azərbaycan  Српски

Српски  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  Cymraeg

Cymraeg  Беларус

Беларус  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Bosanski

Bosanski  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  IsiXhosa

IsiXhosa  Chichewa

Chichewa  Somali

Somali  O'zbek

O'zbek  հայերեն

հայերեն  Sundanese

Sundanese  Malagasy

Malagasy