PRODUCT NAME:

100T per day disc round lead anode casting machine of scrap lead battery recycling for electrolysis system

The Method and Function of Refining Crude Lead in Lead Smelting Furnace

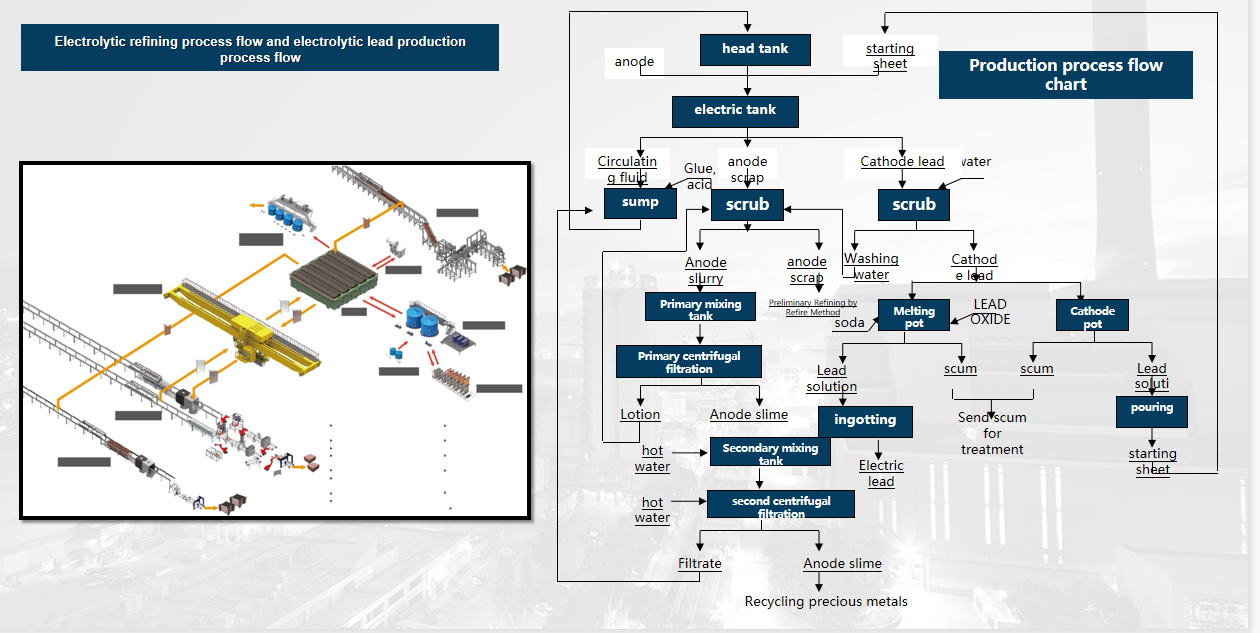

Introduction to Lead Smelting Furnace Equipment Manufacturers: Lead smelting furnace, as the name suggests, is a type of furnace used for lead smelting. Using a lead smelting furnace for crude lead refining can not only remove impurities, but also recover metals, achieving resource reuse. There are generally two methods for refining crude lead:

1. Fire refining: It has the advantages of low investment, simple smelting equipment, low investment, small footprint, and the ability to use different processes according to the composition of crude lead and market demand, resulting in the production of various grades of refined lead. Fire refining is more suitable for crude lead with less bismuth and precious metals.

2. Electrolytic refining: It can enrich bismuth and precious metals in anode mud, which is conducive to comprehensive recovery. Therefore, the metal recovery rate is high, the labor conditions are good, and high purity refined lead is produced.

It should be noted that due to the fact that most domestic factories use air oxidation to remove tin, electrolytic refining is generally the main method for crude lead in China.

PRODUCT PICTURES:

100T per day disc round lead anode casting machine of scrap lead battery recycling for electrolysis system

100T per day disc round lead anode casting machine of scrap lead battery recycling for electrolysis system

100T per day disc round lead anode casting machine of scrap lead battery recycling for electrolysis system

SPECIFICATIONS:

100T per day disc round lead anode casting machine of scrap lead battery recycling for electrolysis system

English

English  Español

Español  Português

Português  русский

русский  français

français  日本語

日本語  Deutsch

Deutsch  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ไทย

ไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  Malay

Malay  বাংলা

বাংলা  हिन्दी

हिन्दी  Pilipino

Pilipino  Türk

Türk  عربى

عربى  Indonesia

Indonesia  norsk

norsk  čeština

čeština  Українська

Українська  Javanese

Javanese  فارسی

فارسی  తెలుగు

తెలుగు  Burmese

Burmese  български

български  Latine

Latine  Azərbaycan

Azərbaycan  Српски

Српски  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  Cymraeg

Cymraeg  Беларус

Беларус  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Bosanski

Bosanski  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  IsiXhosa

IsiXhosa  Chichewa

Chichewa  Somali

Somali  O'zbek

O'zbek  հայերեն

հայերեն  Sundanese

Sundanese  Malagasy

Malagasy