PRODUCT NAME:

10T equipment lead liquid mixer machine for lead smelting pot of scrap lead battery recycle

Lead pot mixer

Suitable for slowly rotating and stirring the lead solution in crucible type lead furnaces, pool type lead furnaces, reflective lead furnaces, lead solution pouring bags, and static boxes;

1. The equipment uses a crane to lift the disc cover and install it at the furnace mouth, which is simple and fast;

2. Adopting stainless steel shaft configuration with impeller rotation for high-power rapid mixing (the mixing shaft is provided by the buyer).

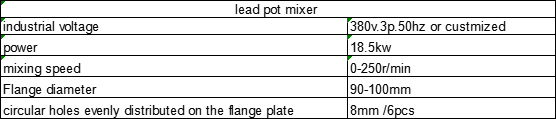

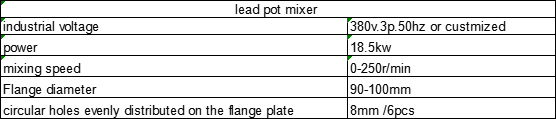

1. Rated power supply: 3-phase, 380V.

2. Rated frequency: 50Hz.

3. Rotor spindle turbine reducer motor: 18.5KW;

4. Rotary shaft speed: 0-250r/min (speed control motor+digital display speed control meter);

5. The diameter of the upper flange plate connecting the stainless steel mixing shaft is 90~100mm, and six 8mm circular holes are evenly distributed on the flange plate;

6. Set necessary indicator lights for the electronic control system: power supply, operation, emergency stop button, start/stop button, etc; Each button is clearly and securely labeled.

1. One hoisting mixer; 2. 1 mobile bracket (convenient for placing the hanging disc mixer when not in operation);

3. One electric control box; 4. One circuit diagram instruction manual.

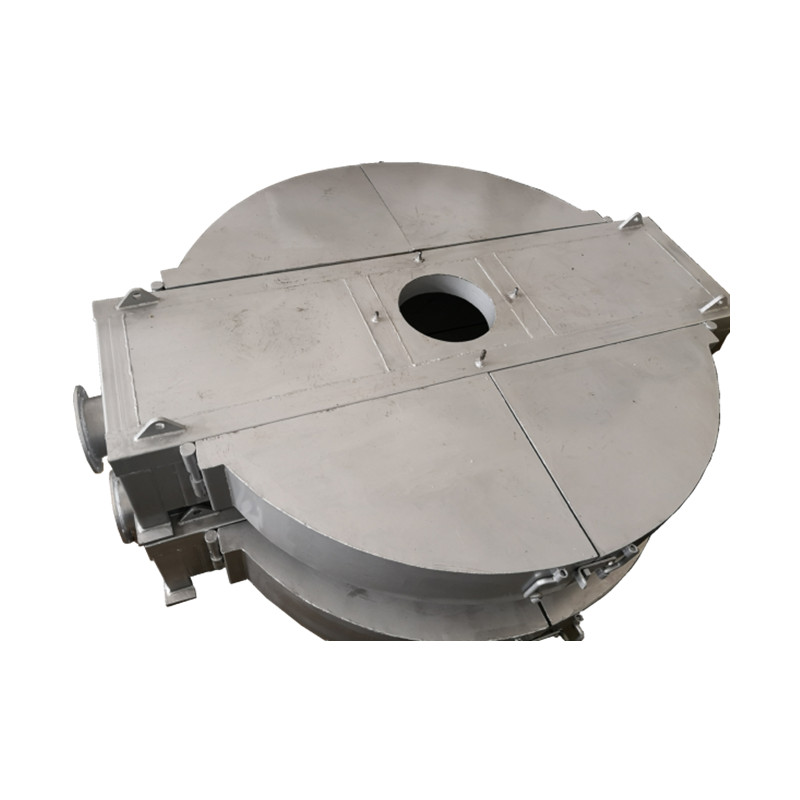

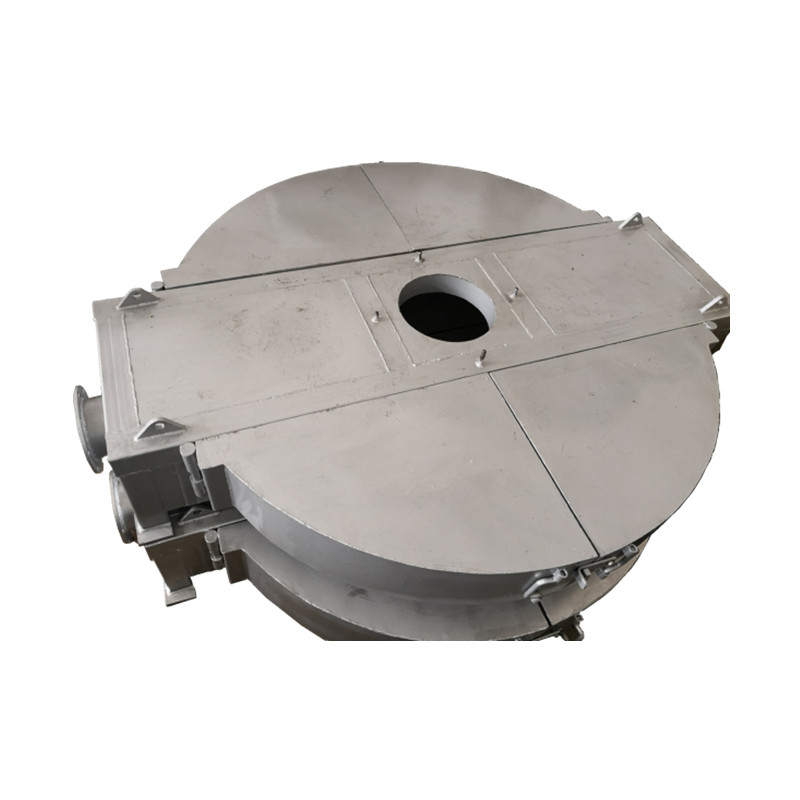

PRODUCT PICTURES:

10T equipment lead liquid mixer machine for lead smelting pot of scrap lead battery recycle

10T equipment lead liquid mixer machine for lead smelting pot of scrap lead battery recycle

10T equipment lead liquid mixer machine for lead smelting pot of scrap lead battery recycle

SPECIFICATIONS:

10T equipment lead liquid mixer machine for lead smelting pot of scrap lead battery recycle

English

English  Español

Español  Português

Português  русский

русский  français

français  日本語

日本語  Deutsch

Deutsch  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ไทย

ไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  Malay

Malay  বাংলা

বাংলা  हिन्दी

हिन्दी  Pilipino

Pilipino  Türk

Türk  عربى

عربى  Indonesia

Indonesia  norsk

norsk  čeština

čeština  Українська

Українська  Javanese

Javanese  فارسی

فارسی  తెలుగు

తెలుగు  Burmese

Burmese  български

български  Latine

Latine  Azərbaycan

Azərbaycan  Српски

Српски  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  Cymraeg

Cymraeg  Беларус

Беларус  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Bosanski

Bosanski  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  IsiXhosa

IsiXhosa  Chichewa

Chichewa  Somali

Somali  O'zbek

O'zbek  հայերեն

հայերեն  Sundanese

Sundanese  Malagasy

Malagasy