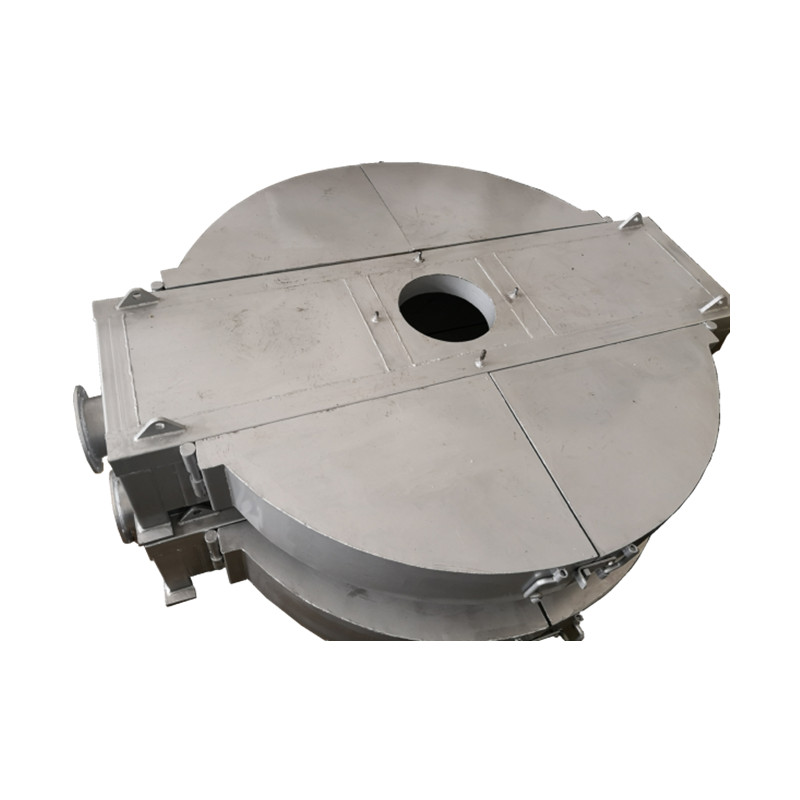

PRODUCT NAME: China factory supply lead paste lead grid refining kettle lead smelting furnace

Crude lead smelting, casting, and exhaust gas treatment system

1. Refining lead smelting flow diagram

2. Refining lead production and description:

2.1 Capacity:Refining lead-----25 tons/batch(slag =2%-4%)

2.2 Device:3pcs refining kettles(25T)(1xlead smelting, 2x heat accumulation)

2.3 Wet lead refining:

Heating the kettle first, then put wet lead in, stirring constantly while smelting, add sulfur to remove copper. Heating the lead liquid to 420 ℃ ~ 450 ℃, and then adding alkali, nitrate, sodium chloride and constantly to remove slag. Remove tin and bismuth when necessary.

2.4 Refining lead ingoting:

Alloy lead liquid pumping lead kettle for storing heat, according to the company's requirements modulation alloy, adopt bottom streaming method to do lead alloy ingot casting. Ingot casting using small pot in the middle as buffer device, through the radial roller wheel continuous pouring, each unit ingot casting machine is 20 tons per hour, lead ingot is 24 kg/piece (48 kg) or according to customer requirements to design, finally complete the lead ingot stacking, packing, weighing, post code, etc.

2.5 Flue gas treatment system:

Exhaust gas by cyclone dust collector draught fan, and chimney, plastic plate processing equipment collected and disposal in the refining process, when the tail gas meet the discharge standards of environmental protection of the local, discharged into the atmosphere.

PRODUCT PICTURES:

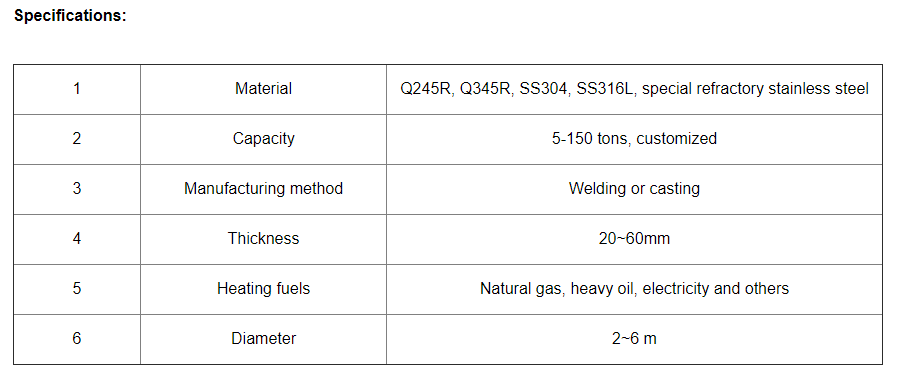

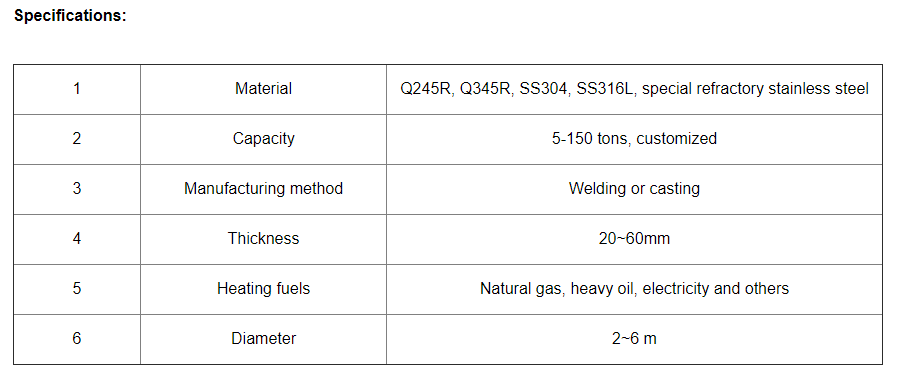

SPECIFICATIONS: China factory supply lead paste lead grid refining kettle lead smelting furnace

English

English  Español

Español  Português

Português  русский

русский  français

français  日本語

日本語  Deutsch

Deutsch  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ไทย

ไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  Malay

Malay  বাংলা

বাংলা  हिन्दी

हिन्दी  Pilipino

Pilipino  Türk

Türk  عربى

عربى  Indonesia

Indonesia  norsk

norsk  čeština

čeština  Українська

Українська  Javanese

Javanese  فارسی

فارسی  తెలుగు

తెలుగు  Burmese

Burmese  български

български  Latine

Latine  Azərbaycan

Azərbaycan  Српски

Српски  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  Cymraeg

Cymraeg  Беларус

Беларус  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Bosanski

Bosanski  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  IsiXhosa

IsiXhosa  Chichewa

Chichewa  Somali

Somali  O'zbek

O'zbek  հայերեն

հայերեն  Sundanese

Sundanese  Malagasy

Malagasy