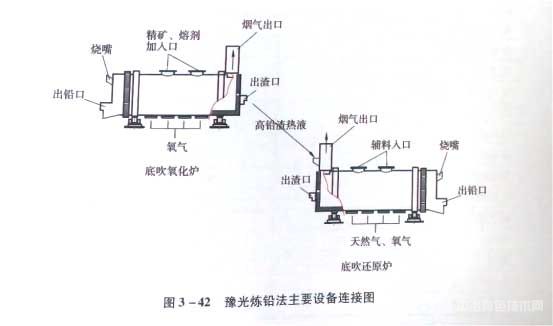

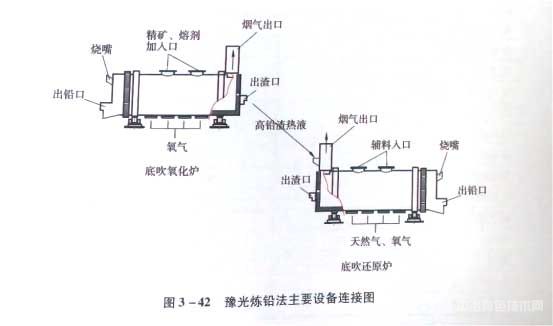

Yuguang three-stage furnace lead smelting method

The main process of Yuguang three-stage furnace lead smelting is bottom blowing furnace oxidation desulfurization, bottom blowing furnace reduction, and fuming furnace recovery of zinc. It was industrialized and applied in 2010. Cancel the blast furnace, eliminate metallurgical coke, and achieve direct reduction of liquid slag. Together with the original oxygen enriched bottom blowing furnace oxidation section, form a complete industrial production system for direct reduction of liquid slag. The specific technical solution is to mix lead concentrate, limestone, quartz sand, etc. and send them to an oxygen bottom blowing furnace for smelting, producing crude lead, liquid slag, and dusty flue gas. Liquid high lead slag is directly fed into the horizontal reduction furnace, with natural gas and oxygen supplied by the bottom spray gun, and a feeding port provided at the top for adding coal particles and stones. The slag is discharged intermittently. The partial oxidation combustion of natural gas and coal particles releases heat, maintaining the temperature required for the reduction reaction. Under gas stirring and mass transfer, the reduction of high lead slag is achieved.

English

English  Español

Español  Português

Português  русский

русский  français

français  日本語

日本語  Deutsch

Deutsch  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ไทย

ไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  Malay

Malay  বাংলা

বাংলা  हिन्दी

हिन्दी  Pilipino

Pilipino  Türk

Türk  عربى

عربى  Indonesia

Indonesia  norsk

norsk  čeština

čeština  Українська

Українська  Javanese

Javanese  فارسی

فارسی  తెలుగు

తెలుగు  Burmese

Burmese  български

български  Latine

Latine  Azərbaycan

Azərbaycan  Српски

Српски  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  Cymraeg

Cymraeg  Беларус

Беларус  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Bosanski

Bosanski  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  IsiXhosa

IsiXhosa  Chichewa

Chichewa  Somali

Somali  O'zbek

O'zbek  հայերեն

հայերեն  Sundanese

Sundanese  Malagasy

Malagasy