1、 Overview of Bismuth

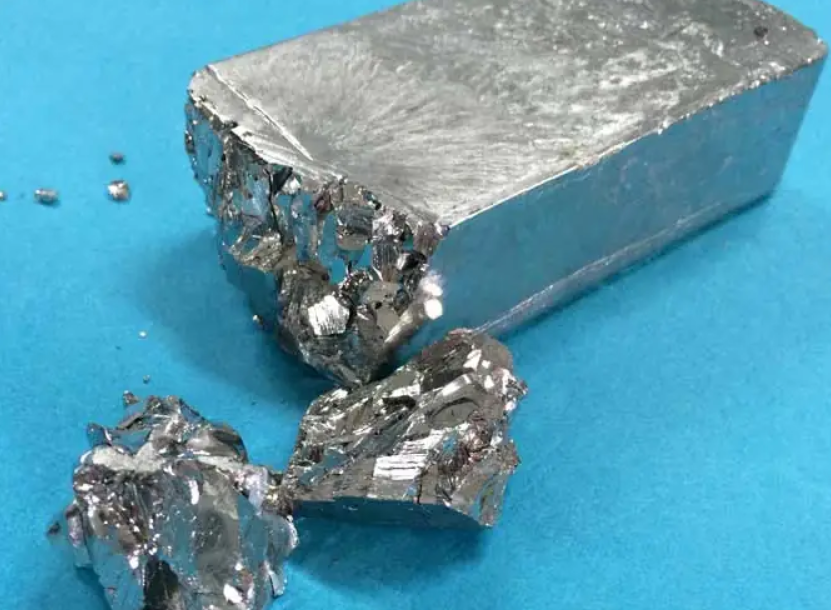

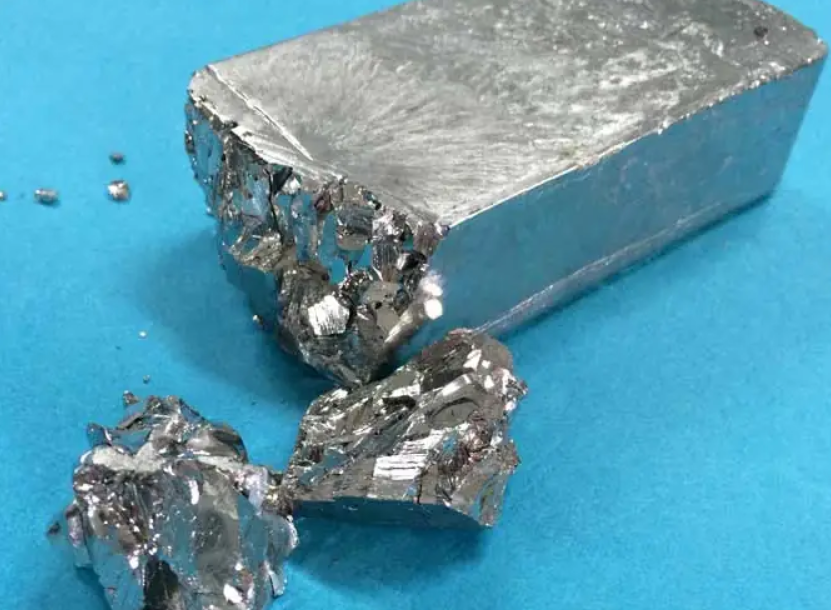

Bismuth is a white or silver white metal with an atomic number of 83, belonging to the sixth period and group VIII elements. In nature, bismuth is mainly sulfided

The form of mineral exists. Bismuth has good ductility, conductivity, and corrosion resistance, making it widely used in the industrial field.

2、 The smelting method of bismuth

1. Pyrometallurgical smelting

Pyrometallurgical smelting is the process of crushing, grinding, and flotation of bismuth containing ores to obtain bismuth containing concentrates. Then the bismuth containing concentrate is smelted at high temperature to obtain

To coarse bismuth. In the pyrometallurgical process, commonly used fluxes include limestone, quartz, etc., to lower the melting point of slag and reduce harmful gas emissions.

2. Wet smelting

Wet smelting mainly extracts bismuth from bismuth containing ores through chemical reactions. The commonly used methods include sulfuric acid method, nitric acid method, etc. The sulfuric acid method involves mixing bismuth containing ore with sulfuric acid

Combine to generate bismuth sulfate solution, and then extract bismuth through a series of chemical reactions. The nitric acid method involves mixing bismuth containing ore with nitric acid to produce a bismuth nitrate solution, which is then reduced

The agent reduces bismuth.

3. Electrolytic smelting

Electrolytic smelting is the process of separating metallic bismuth from a bismuth containing solution through electrolysis. During the electrolysis process, bismuth ions in the bismuth containing solution obtain electrons at the cathode, generating

Become metallic bismuth. The electrolysis method has the advantages of high production efficiency and low energy consumption.

English

English  Español

Español  Português

Português  русский

русский  français

français  日本語

日本語  Deutsch

Deutsch  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ไทย

ไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  Malay

Malay  বাংলা

বাংলা  हिन्दी

हिन्दी  Pilipino

Pilipino  Türk

Türk  عربى

عربى  Indonesia

Indonesia  norsk

norsk  čeština

čeština  Українська

Українська  Javanese

Javanese  فارسی

فارسی  తెలుగు

తెలుగు  Burmese

Burmese  български

български  Latine

Latine  Azərbaycan

Azərbaycan  Српски

Српски  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  Cymraeg

Cymraeg  Беларус

Беларус  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Bosanski

Bosanski  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  IsiXhosa

IsiXhosa  Chichewa

Chichewa  Somali

Somali  O'zbek

O'zbek  հայերեն

հայերեն  Sundanese

Sundanese  Malagasy

Malagasy