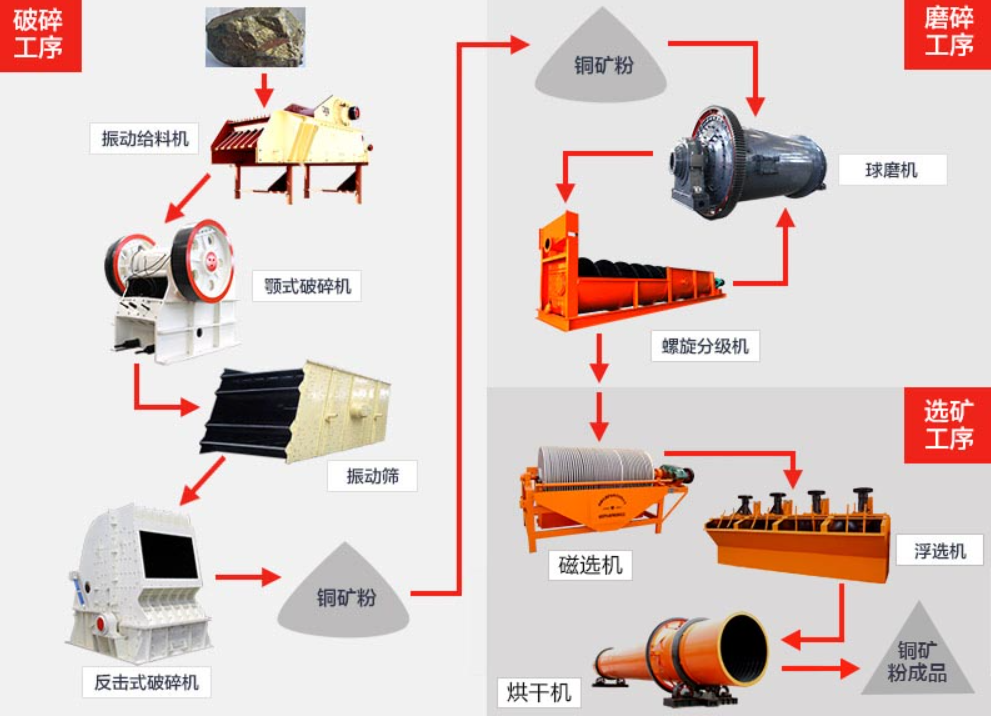

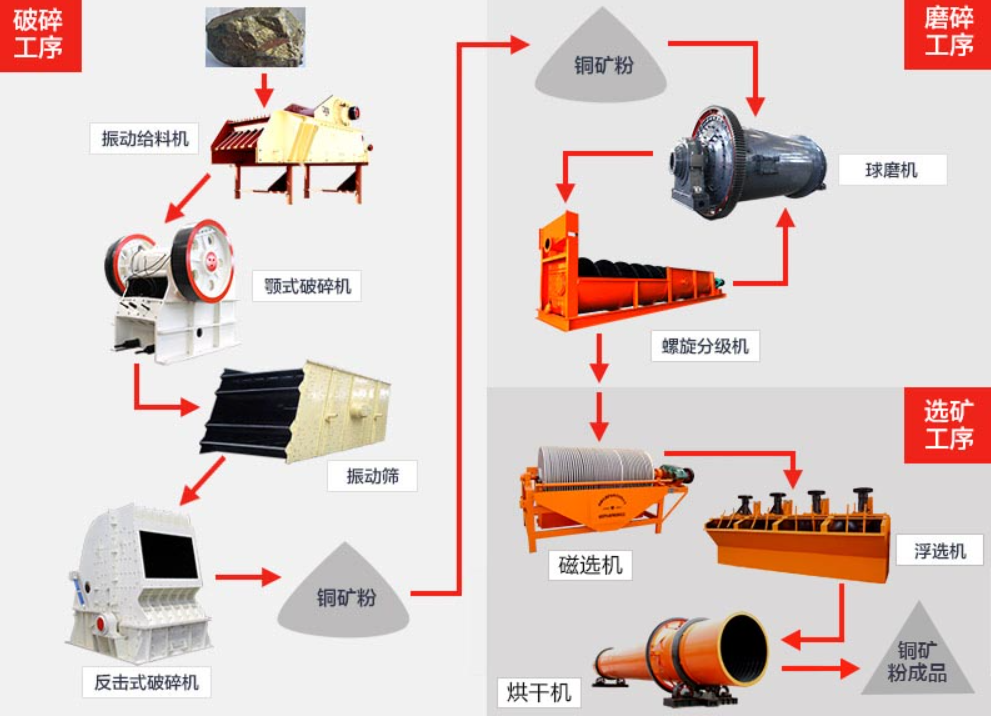

Mineral selection methods and processes for copper mines

The beneficiation methods and processes for copper mines mainly include the following:

Flotation method:

Priority flotation method: When the ore contains two or more useful minerals and is processed by flotation, the useful minerals are selected one by one as a single concentrate in the flotation process.

Mixed flotation method: Various useful minerals in the ore are selected together to form a mixed concentrate, and then the various useful minerals are separated.

Emulsion flotation method: Copper oxide minerals are first sulfided, and then covered with a neutral oil emulsion to create a strongly hydrophobic floatable state, allowing the minerals to adhere to bubbles for separation.

Sulfide flotation method (including conventional sulfide flotation and hydrothermal sulfide flotation): mainly used for processing copper oxide minerals such as malachite and azurite.

Segregation copper refining method:

Suitable for ores that cannot be processed by beneficiation and general metallurgical methods, high concentrate and copper recovery can be obtained, but the investment and production costs are relatively high.

Magnetic Separation Method:

According to the different magnetic properties of impurities in copper ore, suitable magnetic separators are selected for magnetic separation to remove impurities and select copper ore.

Mechanical selection method:

The use of collision and friction in crushers to remove impurities from copper ore is currently less common due to its low efficiency.

In addition, there is also a method of enriching with a jigs and then flotation, which is suitable for the beneficiation of low-grade copper ore, and can reduce beneficiation costs and improve concentrate grade.

In the process of mineral processing, commonly used equipment includes flotation machines, magnetic separators, ball mills, crushers, etc. The selection of mineral processing technology should be determined based on the specific properties and composition of the ore, as well as the mineral processing test report, in order to achieve the best mineral processing effect and economic benefits.

English

English  Español

Español  Português

Português  русский

русский  français

français  日本語

日本語  Deutsch

Deutsch  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ไทย

ไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  Malay

Malay  বাংলা

বাংলা  हिन्दी

हिन्दी  Pilipino

Pilipino  Türk

Türk  عربى

عربى  Indonesia

Indonesia  norsk

norsk  čeština

čeština  Українська

Українська  Javanese

Javanese  فارسی

فارسی  తెలుగు

తెలుగు  Burmese

Burmese  български

български  Latine

Latine  Azərbaycan

Azərbaycan  Српски

Српски  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  Cymraeg

Cymraeg  Беларус

Беларус  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Bosanski

Bosanski  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  IsiXhosa

IsiXhosa  Chichewa

Chichewa  Somali

Somali  O'zbek

O'zbek  հայերեն

հայերեն  Sundanese

Sundanese  Malagasy

Malagasy